What’s interesting is how this affects the geometry related to those ‘edges’. But by throwing a section through the part, you can grab the edges (created by the section) and move them into the position required. This isn’t necessarily the easiest thing to accomplish when direct editing faces. In addition to pushing and pulling faces, edges can now be manipulated with the system handling geometry adaptation The first is that in some cases, the internal geometry of a part needs to be edited.įig 3. The concept is that when using direct editing, you edit a cross section of the part, rather than the faces and edges. Those that have seen or worked with SpaceClaim will be immediately familiar with this. They can now be used when working with a cross section placed through the part. Now that we’ve established what Siemens has added into sketching regarding Synchronous Technology, let’s explore how those same tools are available for use in the 3D environment. These can be done either from the centre of a pocket or by the centre of each fillet. The same is true of the new edits to fillets in sketches. Again, this is a subtle change/addition, but it gives more control when adapting geometry. Rather than pure move operations, you can now also offset them. One is how the system handles moving entities.

UG NX 8.5 MANUAL UPDATE

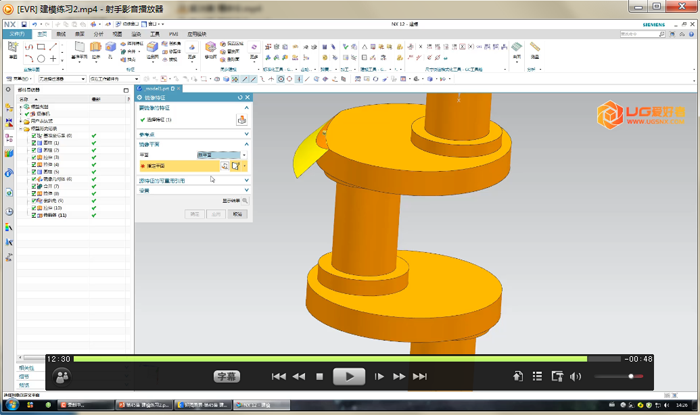

This means that legacy drawings can be edited with the same tools and dimensions will update where needed.Įlsewhere in sketching, there are additional updates to a couple of operations that are worthy of note. It’s also interesting to note that the same tools will work on imported 2D data, where the usual caveats of good clean geometry apply. It won’t remove the need to add those constraints, at the early stages of sketch layout, but it’ll be invaluable - particularly if your working methods are based on top down, sketch driven assembly design. While it’s subtle, the end result is being able to make edits to unconstrained geometry that are much more predictable. Without explicitly having to apply constraints, the system will find areas of tangency, symmetry and such. Synchronous Technology for sketching uses the same live relationship detection and management tools found in geometry manipulation, but in a sketching environment, with the Curve Finder. But it’s often the case that doing so will result in a nightmare where tangency between lines and arcs will flip and other geometry will shift in an undesirable manner. Most systems include some sort of predictive constraints placement. You’ll be familiar with what happens when you drag and drop entities in a sketch that aren’t constrained. Imagine, if you will, that you’re working with those fundamental sketches that drive feature creation. While the Synchronous Technology tools for 3D geometry continue to mature and evolve with this release (we’ll get onto that shortly), there’s been a focus on introducing the same concepts to other areas of the system too - namely, sketching. Synchronous Technology has been extended to allow editing of geometry using a dynamic cross section What differs in the NX world is how these tools are both intelligent (in terms of automatic detection of geometry conditions) and integrated into the existing tools.įig 2. The ability to push, pull and generally wrangle geometry directly, without having to edit history, is something that’s become prevalent in many systems in one way or another. Sketching gets sync techīy now, we should all be aware of how Synchronous Technology works in the realm of geometry manipulation. Now, you can tap in a search term and it’ll not only provide direct access to the help for that feature, but will show where it is. While it’s been there for a while, it’s now directly within the UI. The third is that the Command Finder has been enhanced. I’m sure most users will quickly adapt it to suit their most common workflows. Panels can now be added and commands switched in and out where needed. The second is that it’s entirely customisable. That means all the tools needed for a specific job are available and ready to go.

The first is that all of the system’s commands, by default, have been arranged in tabs by process or workflow. Siemens has done a pretty solid job of easing this transition, which has been accomplished in a few ways. But (and there’s always a but) that UI is very specific to NX and, although Siemens has now adopted the now familiar ribbon style UI, I can imagine that long-term users will be throwing their arms up in frustration.

The UI, as it stands now, is clean, polished and impressive by anyone’s standards.

0 kommentar(er)

0 kommentar(er)